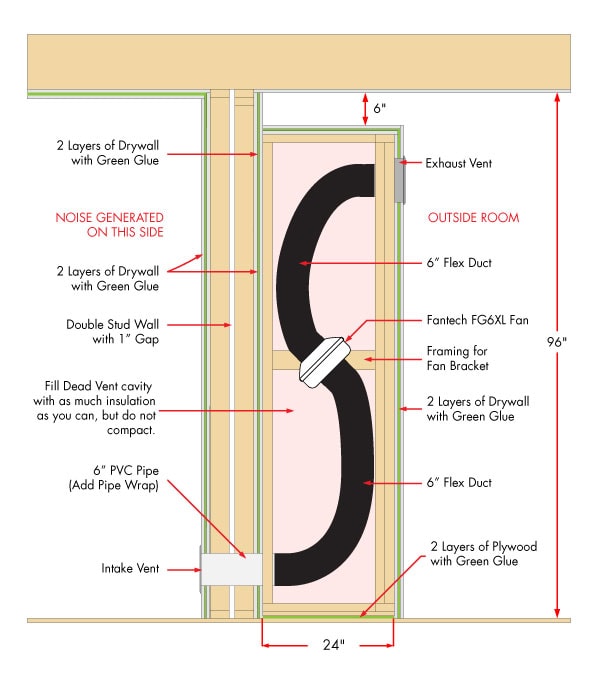

How to build a dead vent soundproofing system

When you create a room of any kind that's dedicated to controlled sound, you will inevitably have sealed it up tighter than a drum. This is great for avoiding flanking noise via leaks, but not so great for cool, fresh air exchange.

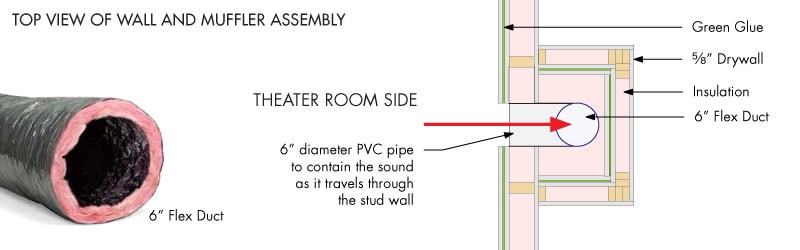

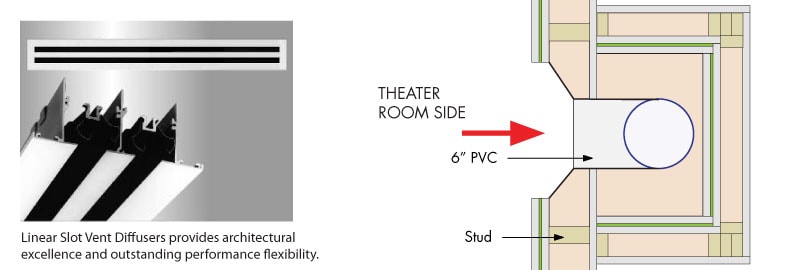

A typical room will need a 6" supply and comparable return. These ducts are a large cross-section for sound to freely escape, regardless of the direction of airflow.

Tying in the room to the main HVAC system, whether in a home or commercial building, introduces the opportunity to pour noise directly into the ductwork.

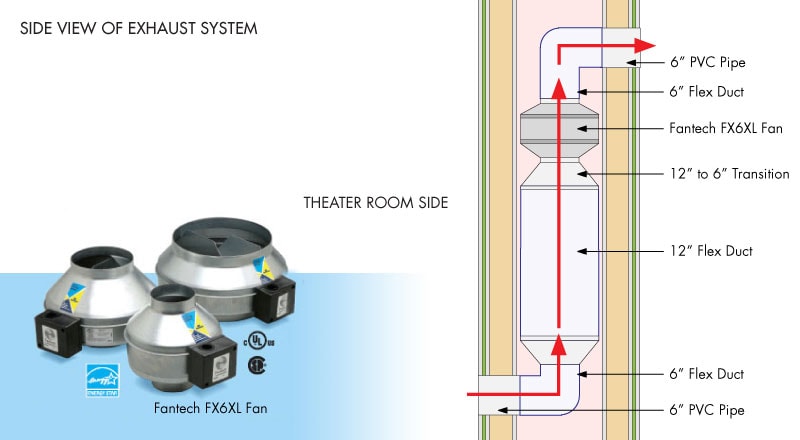

A flanking nightmare, but it doesn't have to be. Consider building a dead vent to muffle the sound as it exits with the air. Ideally, you would have one dead vent for each supply, and one for each air return. You can use a dead vent as a buffer between the sound room and the main HVAC system.

"Subject to local code and HVAC contractor recommendations" Hot air is pulled through soffit to dead vent. The biggest issue with super tight rooms is cooling them. If built below grade (basements, lower levels, etc) consider simply exchanging the theater room air with the rest of the lower level. This avoids tying the sound controlled into the main HVAC.

There are four basic principles at work in the dead vent

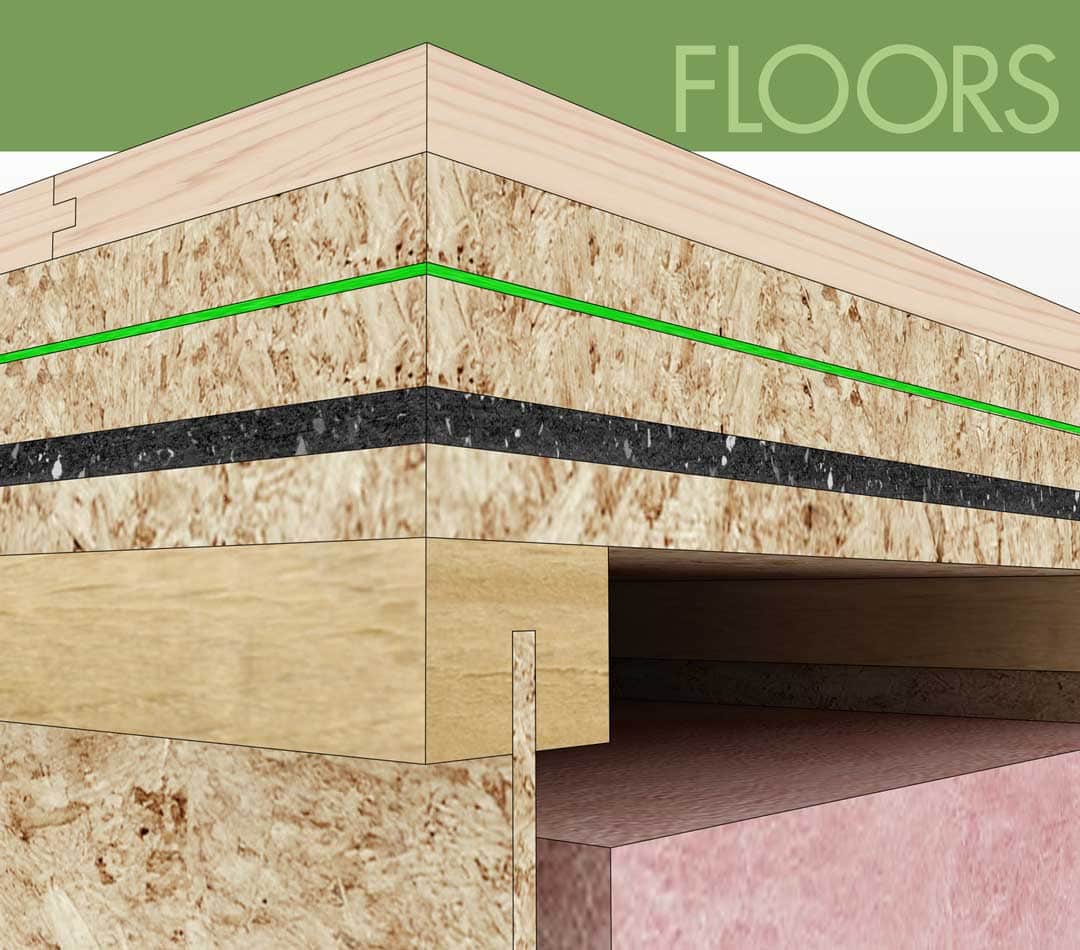

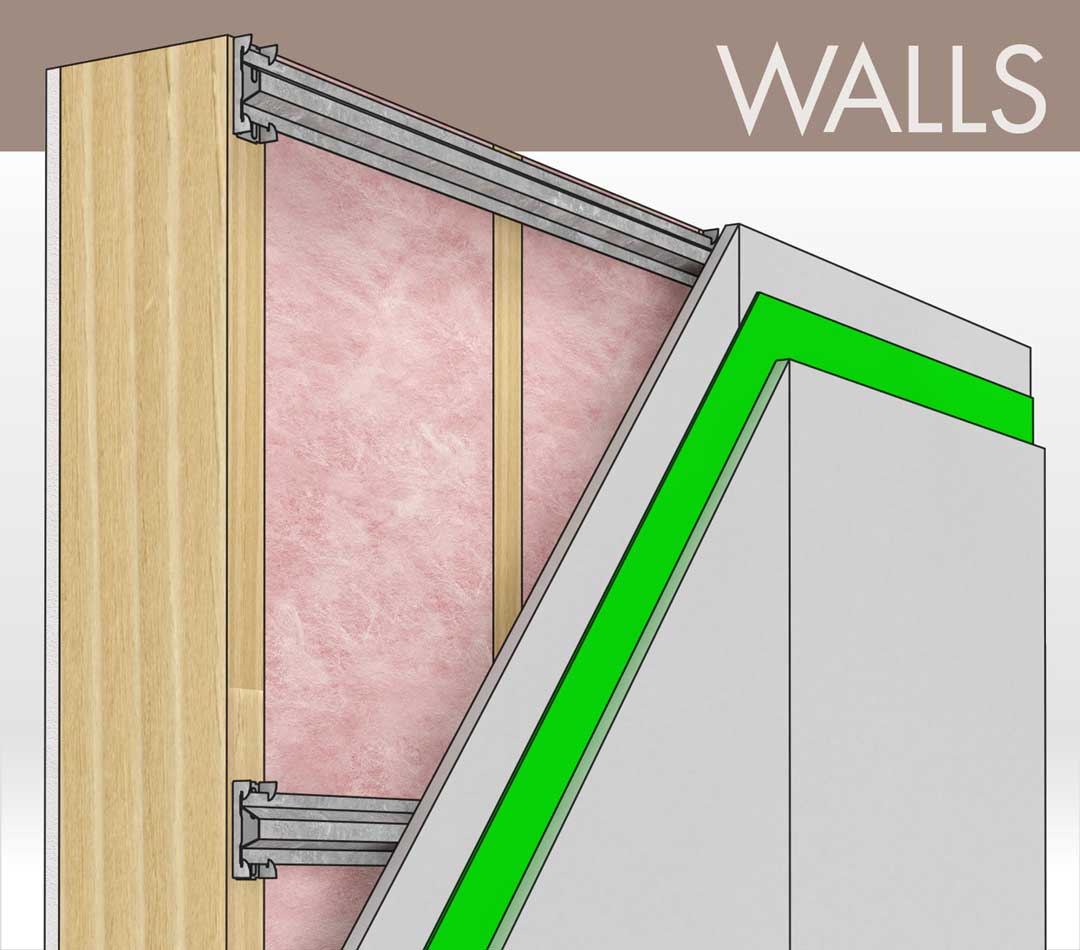

1. A containment structure that is massive and damped.

The entire vent is encased in double 5/8" drywall for mass, and Green Glue for damping. This will not only contain sound but damp it as well.

You can install a flared duct piece here. The significant increase in surface area slows the airspeed, but maintains the volume, so less chance for a large grill cover to whistle. The flare can be 16" wide and 16" tall.

2. Significant absorption within the containment structure.

The structure is filled with fiberglass, mineral wool or a low density fill of cellulose. This insulation will help absorb mid and upper frequency sound.

3. Substantial change in cross sectional area and volume.

This is a fundamental principle behind a silencer for a gun. The large and dramatic increase in the air volume of the silencer relative to the gun barrel is a large part of the function. The 6" diameter supply has a cross-sectional area of about 28 square inches. Compare that to the internal cross-sectional area of the dead vent containment structure of 175 square inches (13.5" x 13.5"). Note that for low frequencies, the flex duct is acoustically transparent, so the entire volume inside the Vent is used for absorption.

4. Forced interaction of the airborne sound with the absorptive material.

A very straight duct run doesn't promote much interaction of sound waves and absorptive material. Having the duct make a few curves or bends forces the sound wave to bump up against absorptive material as the sound wave and air travel through the vent.

Final considerations

- For many rooms including basement home theaters and recording studios, you may only need to consider cooling the air in the room by exchanging this air with the remainder of the basement air. Basements are obviously naturally cool all the time.

- Consider installing a variable speed control. Speed controllers for ceiling fans generally work but check the spec first. Keeping the fan(s) on a low setting all the time will keep the air in the room from becoming musty and stale.

- Consider a dehumidifier outside the dedicated room if you are simply exchanging the air with the balance of the basement air.

- Follow local building codes for construction and ventilation.